| |

|

|

|

|

|

|

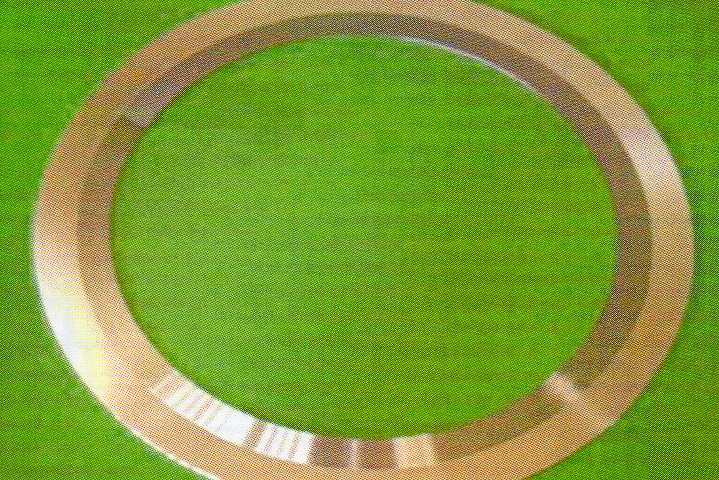

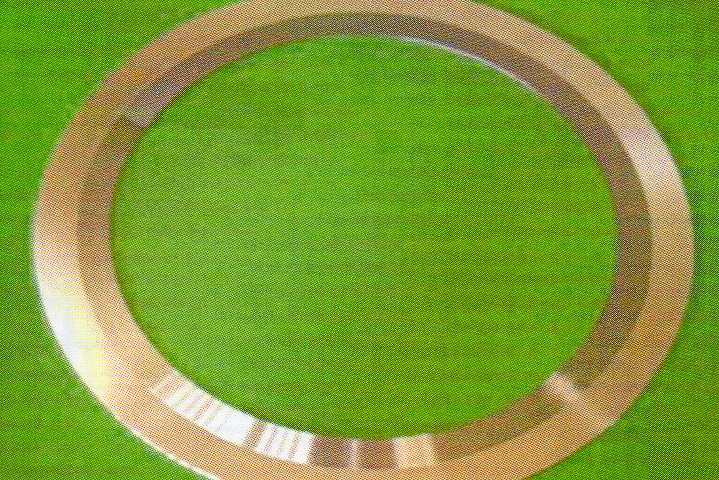

| Type C |

|

|

|

|

| Basic construction style. Suitable for tongue |

|

| and groove, male and female or flat face |

|

| and recess flanges. |

|

|

|

|

|

|

| |

|

|

|

|

|

|

| Type C/IR |

|

|

| Identical to the Type C but fitted with the |

| protective inner ring which gives high |

| pressure and temperature capabilities with |

| improved sealing performance. Used on |

| male and female flanges. |

|

|

| |

|

|

|

|

|

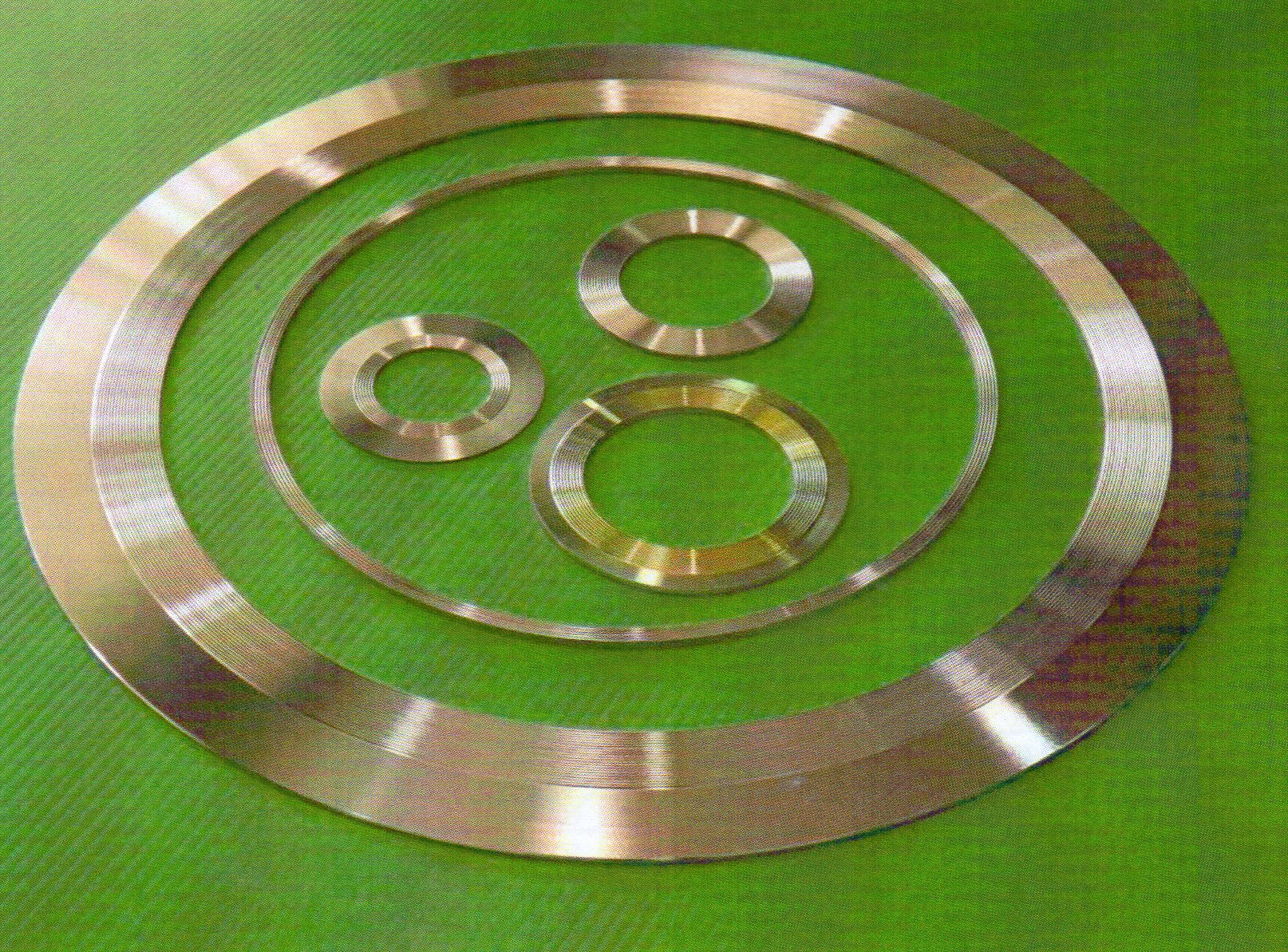

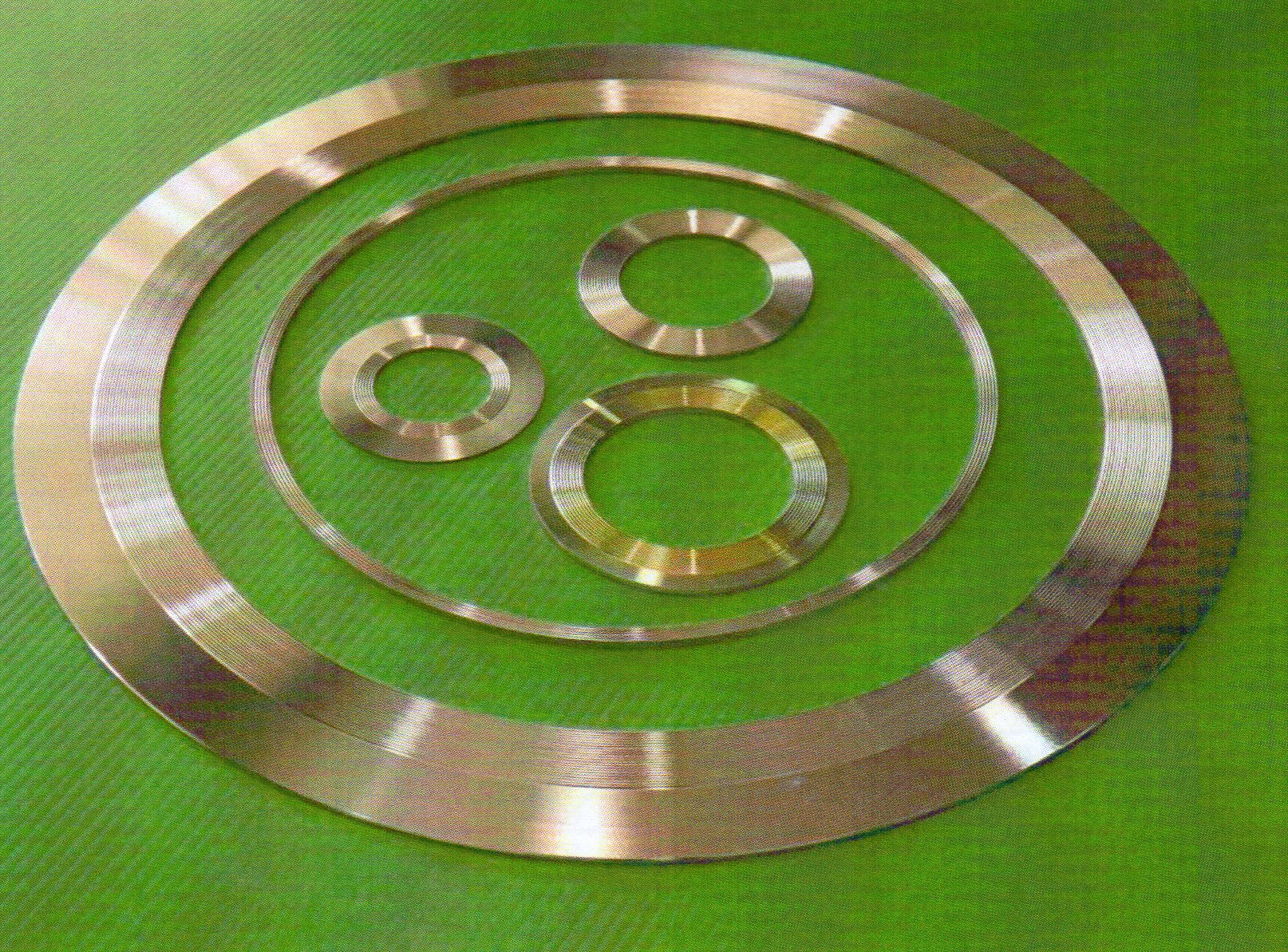

| Type SG |

|

|

|

|

| As Type C but fitted with an external ring |

|

| which accurately centralises the sealing |

|

| element. In addition the ring provides extra |

|

| radial strength and acts as a compression |

|

| stop. Generally used on raised face and flat |

| face flanges.Type |

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|

|

| Type SG/IR |

|

|

|

| Identical to the Type SG but also fitted with |

| an inner ring to prevent damage to the |

|

| gasket bore and inner windings. It also acts |

|

| as a heat shield and corrosion barrier and |

|

| improves recovery characteristics and |

|

| sealing performance. |

|

|

|

|

|

|

.png)

.png)